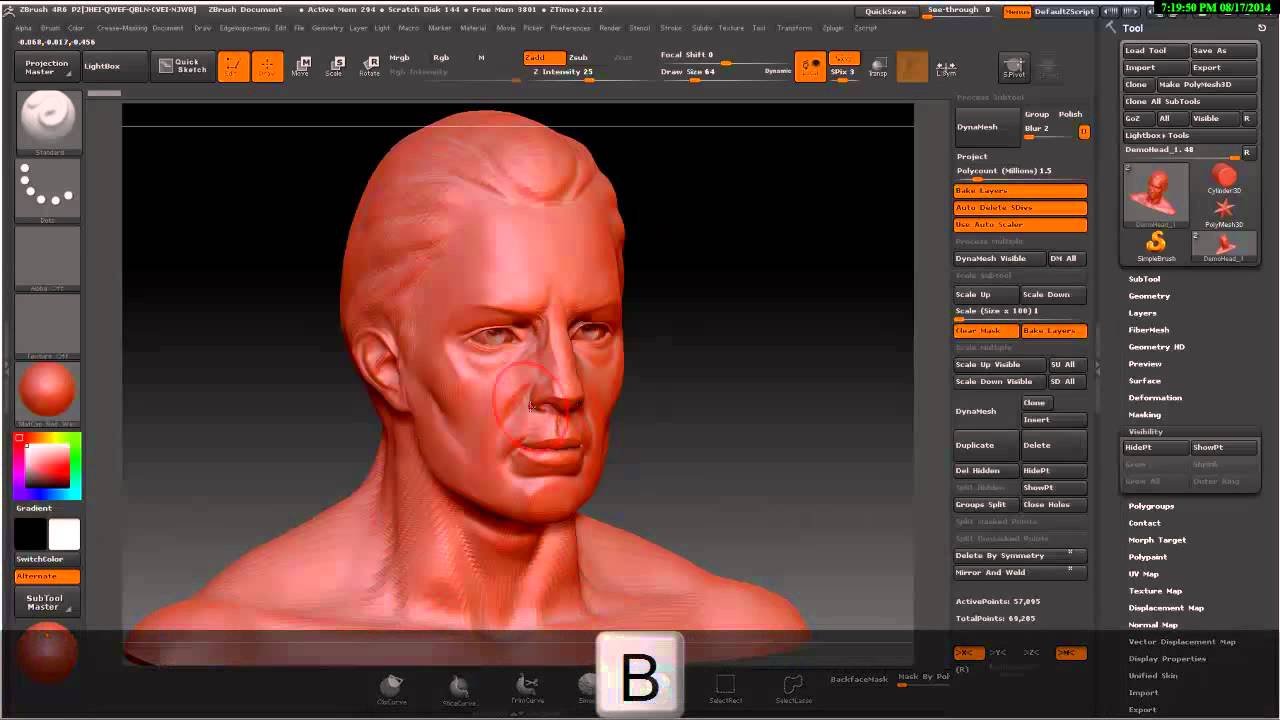

Same as an edge, we can work on polygons shapes group. Now let us take the Zmodeler brush from the Brushes panel, and with this brush, I will place the mouse cursor on the edge of the upper polygroup, make a right-click, and choose Bevel action, then Edge Loop complete option in the Target section.Īnd once I move edges in an inward direction, it will bevel entire edges like this. I will discuss how you can create polygroups later in this article. You’ll be spending way more time trying to fix problems than just letting the printer do it’s thing.I have divided it into some polygroups sections. This is why I wouldn’t cut too much on smaller things.

With the entire part tiny failures can happen but it’s probably not going to be visible in a major way. This is mostly because a tiny failure on part 1 can still print but it won’t fit properly to part 2 anymore. The other thing to worry about with resin is that it can warp on your mating surfaces. Sometimes the gun will end up with the head, sometimes it’ll be on the torso.) would work best. If you really want them in three pieces, I’d think waist, and around the gun (so that you can manipulate it’s orientation. Normally placing it at an angle of around 45 degrees can solve it, but if that makes a situation where one leg is mostly horizontal to the resin vat, you’d want to cut that leg. Resin printers want as little surface area as possible with each dip or it will rip it off the plate or the supports fail and it flattens. The waist is probably a good place to cut them.Īs for the other cuts, it depends on what’s going to give you the best results for the print. I’m going to assume it’s resin and these are probably miniature size. Size is also a consideration, really small objects are hard to handle.

These are resin prints, right? How big are they? Resin has different rules to consider than filament types.

0 kommentar(er)

0 kommentar(er)